- Home

- About Us

- Products

- Case Study

- Videos

- Download

- Support

- Contact Us

COLO-5219

COLO

Width1800 * Height1800 * Depth5000 mm

| Availability: | |

|---|---|

| Quantity: | |

This powder coating oven is designed for curing longer or large workparts in batches. It heats faster using gas or diesel as fuels, and fearures more economical with less energy expense and maintenance cost. The oven is built with durable and high-quality components that never compromise quality and performance.

1. Using PLC system to control all heating process, accurate and conveninet.

2. Riello burner fully burns fuels (gas or diesel), quickly reach to required temperature.

3. Circulation fans causes uniform temperature in the entire chamber that results in quality cured finishes.

4. 100 mm thickness rockwool board always keeps the chamber with minimum heat loss.

5. We can custom powder coating ovens with required sizes, such as 6m, 7m, 8m, or more.

| Model | COLO-5219 |

| Worksize Dimensions | Width1800 * Height1800 * Depth5000 mm |

| Overall Dimensions | Width2100 * Height2200 * Depth5200 mm |

| Power Supply | LPG / Gas / Diesel |

| Voltage/Frequency | 380V/220V (50-60Hz) |

| Warm-up Time | 15-30 min. (180° C) |

| Temperature Stability | < ± 3.0-6°C |

| Temperature | Max. 250° C |

| Transport System | Two trolleys |

| Burner | Italy Riello, 10,0000cal |

| Circulation/ Air flow | Vertical ,Variable through holes on the walls |

| Ventilation Performance | 8288-16576m3/h |

| Motor Power | 7.5kW |

| Warranty | 12 months |

This powder coating oven is designed for curing longer or large workparts in batches. It heats faster using gas or diesel as fuels, and fearures more economical with less energy expense and maintenance cost. The oven is built with durable and high-quality components that never compromise quality and performance.

1. Using PLC system to control all heating process, accurate and conveninet.

2. Riello burner fully burns fuels (gas or diesel), quickly reach to required temperature.

3. Circulation fans causes uniform temperature in the entire chamber that results in quality cured finishes.

4. 100 mm thickness rockwool board always keeps the chamber with minimum heat loss.

5. We can custom powder coating ovens with required sizes, such as 6m, 7m, 8m, or more.

| Model | COLO-5219 |

| Worksize Dimensions | Width1800 * Height1800 * Depth5000 mm |

| Overall Dimensions | Width2100 * Height2200 * Depth5200 mm |

| Power Supply | LPG / Gas / Diesel |

| Voltage/Frequency | 380V/220V (50-60Hz) |

| Warm-up Time | 15-30 min. (180° C) |

| Temperature Stability | < ± 3.0-6°C |

| Temperature | Max. 250° C |

| Transport System | Two trolleys |

| Burner | Italy Riello, 10,0000cal |

| Circulation/ Air flow | Vertical ,Variable through holes on the walls |

| Ventilation Performance | 8288-16576m3/h |

| Motor Power | 7.5kW |

| Warranty | 12 months |

PLC Controller This PLC controller offers all the features you need. the keyboard and LED display allows you to set and read precise temperature as well as duration required. These accurate operations are designed to optimize powder coating effect. |

Gas/Diesel Burner Italy imported Riello gas burner takes full utilizations of fuels, reaching the baking temperature faster, making heating process more efficient and energy-saving. |

Circulation Fan Circulation fan circles the hot air to warm the oven interior, minimize temperature difference and guarantee uniform-heated chamber. There is a isolation strip between fan and motor that tends to protect the motor from burning hot and extend its life. |

Oven Wall Materials Interlayer is rockwool insulation board, 100 mm thickness, density 120kgs/cbm. Together with 1mm heat-resistent galvanized innerwall and 0.7mm durable color steel outwall forms a sandwich structure which is anti-flame and heat-insulation. |

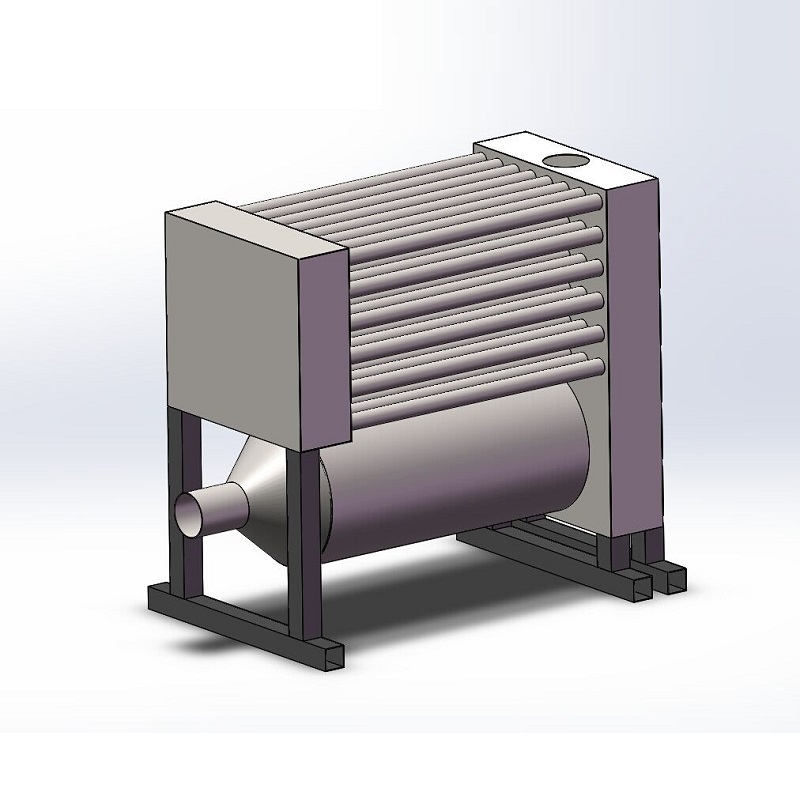

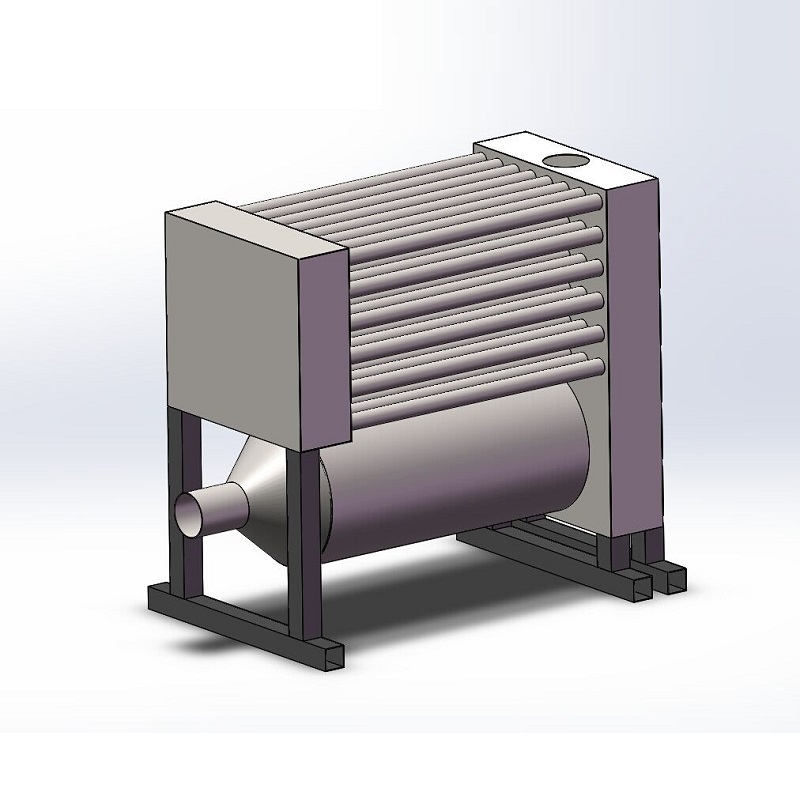

Heating Exchanger It is built inside the burning room. As burners fully burns the fuels at the same time warm-up the heat exchanger. The heat exchange is made of seamless 310S stainless steel pipe in 8x8 array, these pipes are in high temperature thus to heat the air. |

PLC Controller This PLC controller offers all the features you need. the keyboard and LED display allows you to set and read precise temperature as well as duration required. These accurate operations are designed to optimize powder coating effect. |

Gas/Diesel Burner Italy imported Riello gas burner takes full utilizations of fuels, reaching the baking temperature faster, making heating process more efficient and energy-saving. |

Circulation Fan Circulation fan circles the hot air to warm the oven interior, minimize temperature difference and guarantee uniform-heated chamber. There is a isolation strip between fan and motor that tends to protect the motor from burning hot and extend its life. |

Oven Wall Materials Interlayer is rockwool insulation board, 100 mm thickness, density 120kgs/cbm. Together with 1mm heat-resistent galvanized innerwall and 0.7mm durable color steel outwall forms a sandwich structure which is anti-flame and heat-insulation. |

Heating Exchanger It is built inside the burning room. As burners fully burns the fuels at the same time warm-up the heat exchanger. The heat exchange is made of seamless 310S stainless steel pipe in 8x8 array, these pipes are in high temperature thus to heat the air. |